Why Machine Slides Fail and the Impact on Your Production

Unplanned downtime, scrap, and missed deadlines often result from worn or neglected machine slides. Common causes include wear, contamination, lack of lubrication, and material fatigue. When slides are unable to hold tight tolerances or show visible wear and tear, manufacturing equipment may produce nonconforming parts and experience costly stoppages.

Proactive machine repair and rebuild is essential preventive maintenance. Addressing issues early minimizes planned and unplanned downtime, avoids emergency repairs, and extends equipment life. Regular lubrication and scheduled inspections are critical to producing precision parts and consistent quality measurements.

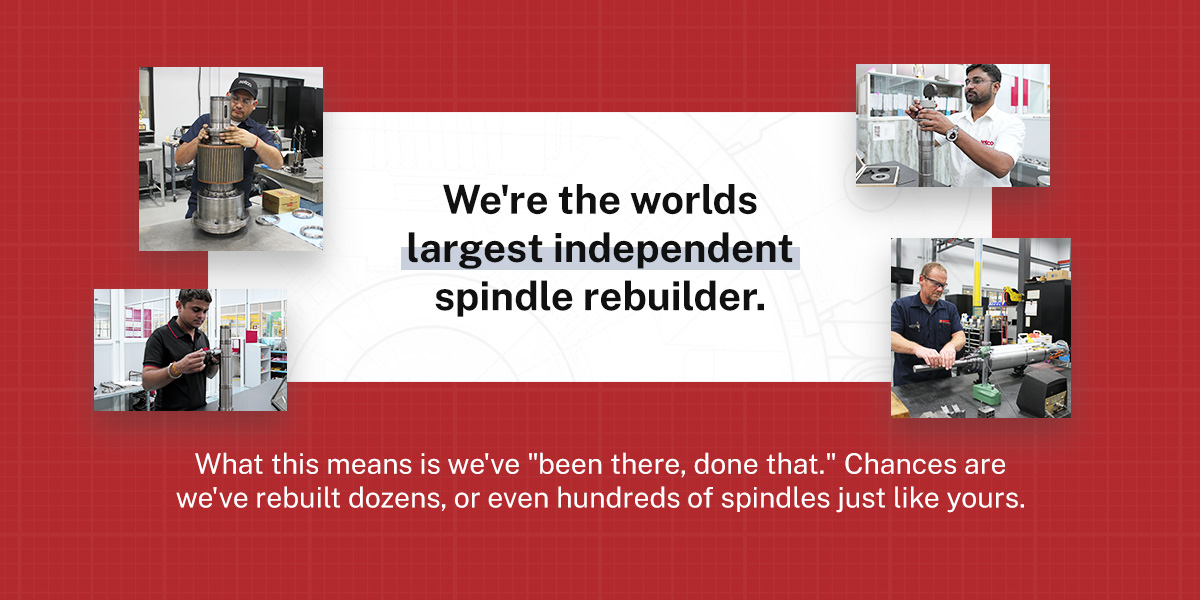

Why Trust Setco for Machine Slide Repair?

Setco is more than a service provider — we serve as a partner in production reliability. Decades of experience, global reach, and technical expertise allow us to repair nearly any slide design or material. Industry professionals recognize us as a worldwide leader in the slide and spindle specialization.

Long-term partnerships are built by delivering the market’s most accurate, durable, and highest-performing products. Our team can walk you through each repair phase, explaining the process required to return your slide to peak operating condition. In addition, we can help evaluate your application to determine whether any other custom slide solutions might be more beneficial.