The Setco™ Spark Erosion Grinding (SEG) System is a NADCAP approved portable electronic discharge machining system that precisely removes metal stock using AC current. The SEG process utilizes EDM technology to arc-grind a profile on metal parts.

For over 30 years the SEG system has been used to machine honeycomb seals and rings for jet engines. Instead of replacing these expensive components, the SEG system can reshape the honeycomb at a fraction of the cost of new replacement parts.

The SEG process is efficient and superior to the mill-type remanufacturing process- typically reducing machine time by 30 to 50%.

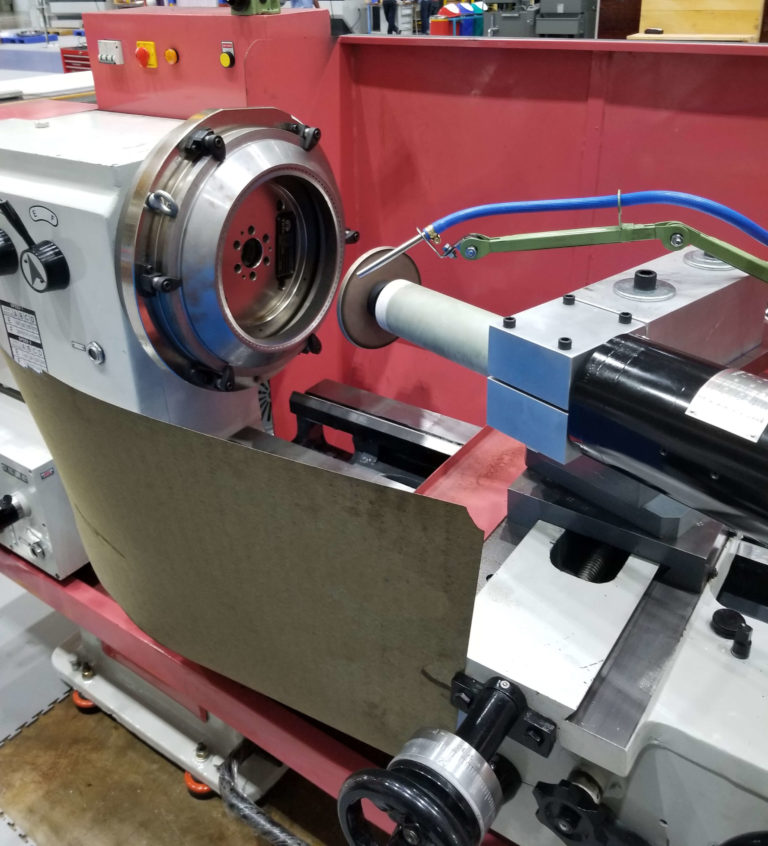

The process is simple. For cylindrical parts, the SEG-125 system is easily adapted to an existing processing center; typically a lathe or turning center is used to secure the honeycomb part and provide part rotation. The SEG spindle is mounted to the cross slide and fed into the part for stock removal. AC Electrical current is fed through the spindle arbor to form a controlled arc between electrode wheel and the metallic honeycomb. As the SEG spindle is fed into part the electric arc erodes away the honeycomb to machine the part to finished diameter.

Download the SEG System brochure for more details and watch the SEG System in action!