Upon receiving the spindle, we will disassemble it, clean the components, and evaluate spindle failure mode to isolate the issues and determine the reason for failure.

We have Setco and GTI service centers across the United States to bring our spindle repair capabilities to OEMs. Before sending us a spindle for repair, download the incoming spindle alert for your nearest Setco or GTI location, and include this form with your shipment.

Setco repairs grinding, milling, routers, drilling, and boring spindles, as well as high-speed spindles up to 150,000 rpm. Our technicians can repair or rebuild nearly all spindle types, including:

Setco repairs spindles for standard and specialized machine tools for just about any application from a wide range of industries, including:

Setco repairs or rebuilds over 14,000 spindles yearly using our comprehensive, multi-step process. Our technicians are equipped to identify problems, complete repairs, and restore the spindle’s performance. These steps include:

Upon receiving the spindle, we will disassemble it, clean the components, and evaluate spindle failure mode to isolate the issues and determine the reason for failure.

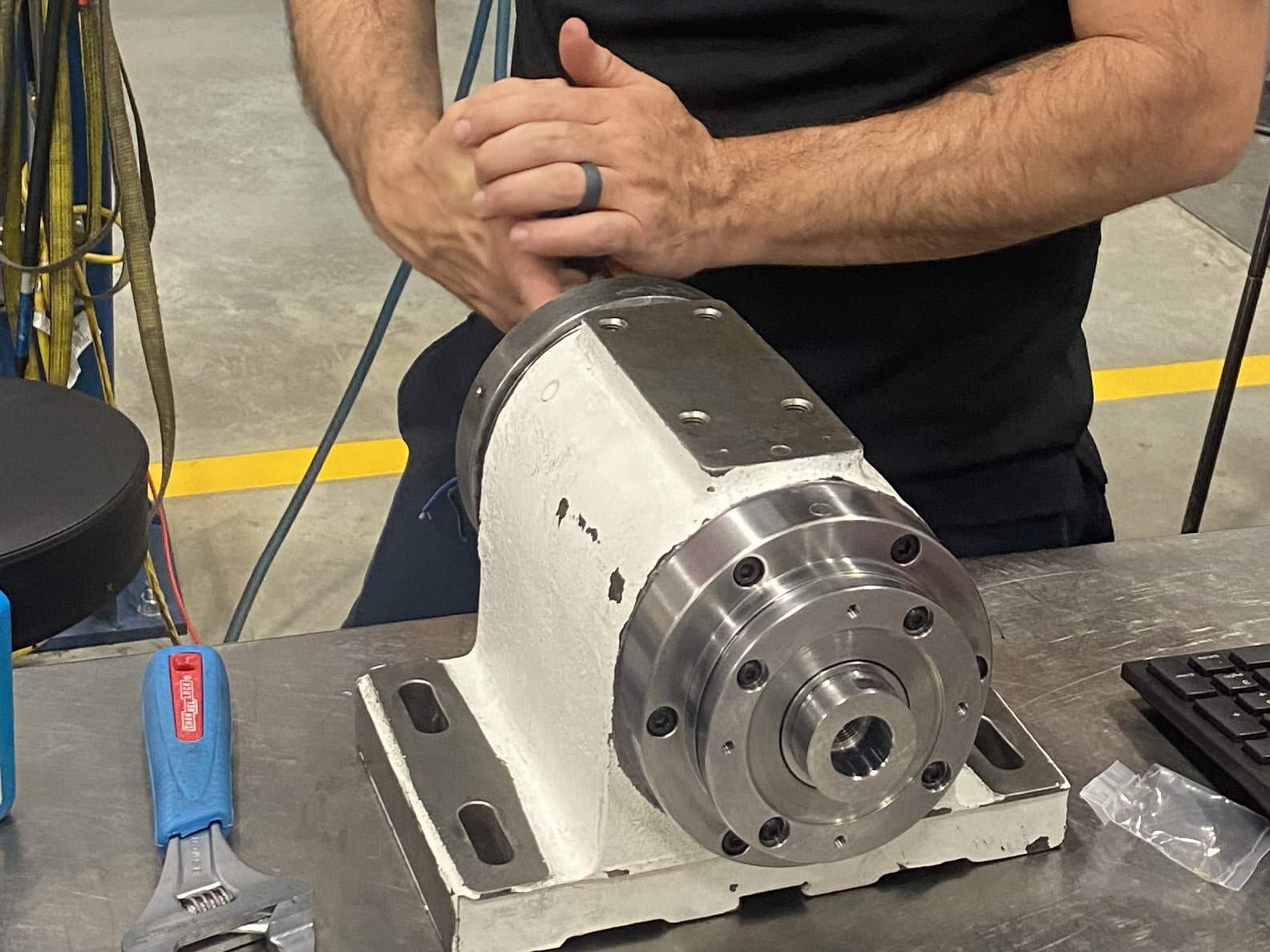

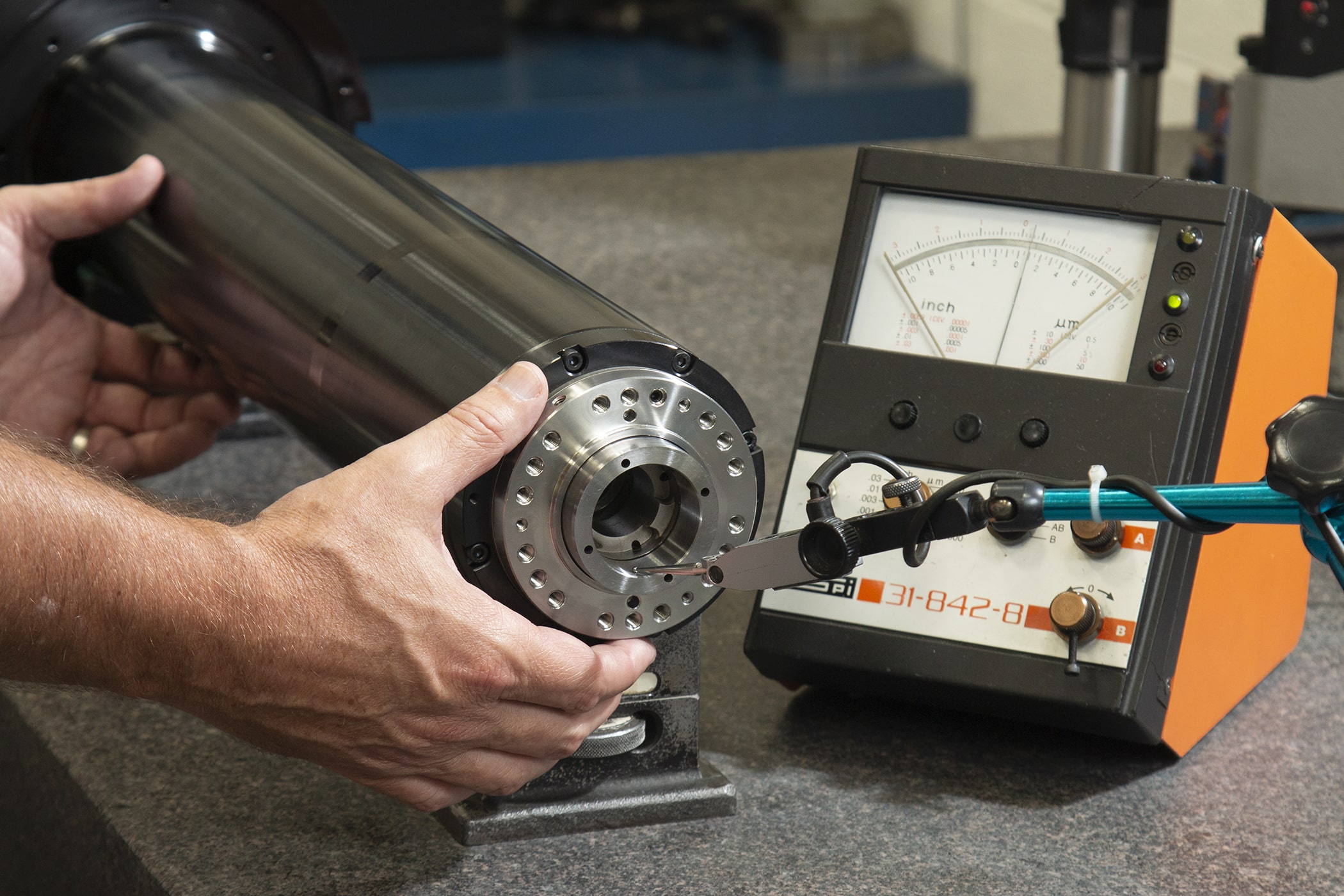

Our technicians will examine the spindle’s most critical components for signs of damage, wear, and improper fit and size. These parts include:

We will create a firm price quote based on the repairs the spindle needs. These quotes are free of charge and without obligation. Once you approve the quote, we’ll start work immediately. If you decline our services, Setco will return the spindle promptly.

We’ll restore the spindle to like-new operating performance by replacing or reconditioning worn parts to OEM specs. This step includes making some of the following repairs:

Setco will reassemble the spindle, perform precision balance, and test to confirm like-new performance. During testing, the spindle will be fully run off under controlled conditions until it’s thermally stabilized at maximum speed. Setco stores baseline vibration and testing data electronically using a serial number for future reference.

Once the spindle has been rebuilt to OEM specifications and passed testing, we’ll send it with full documentation, certification, and a written warranty.

While all spindle repair and rebuild companies have the ability to do a good job on your spindle repairs, Setco is different in some critical areas. We stand out for our: