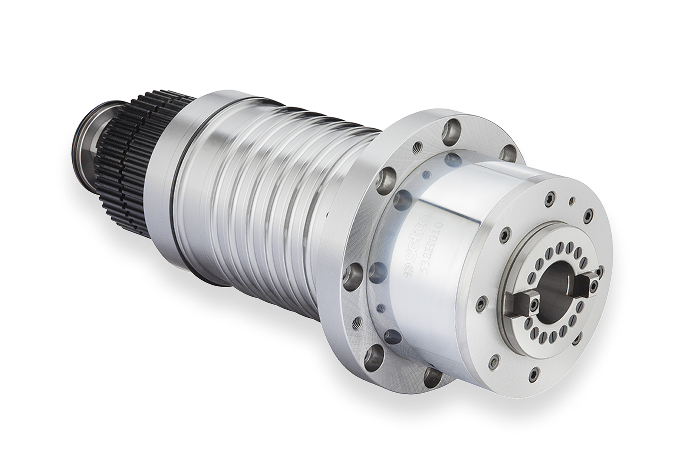

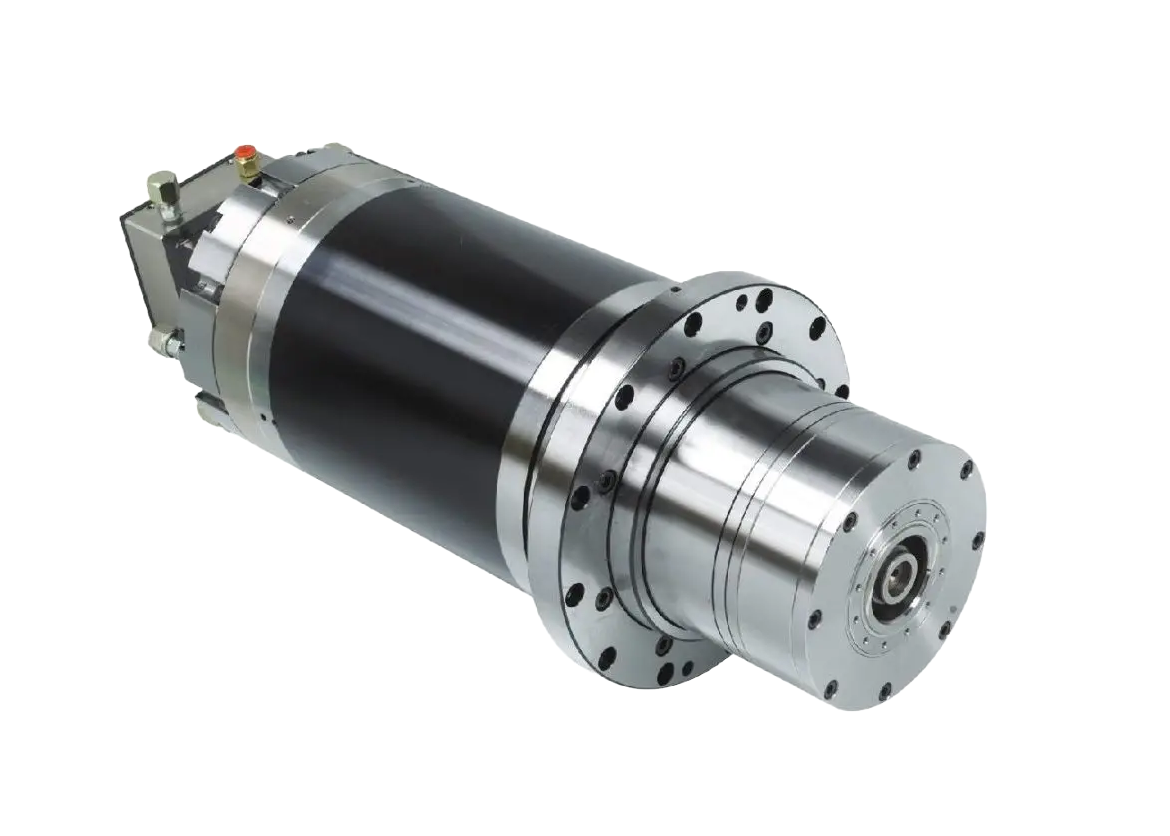

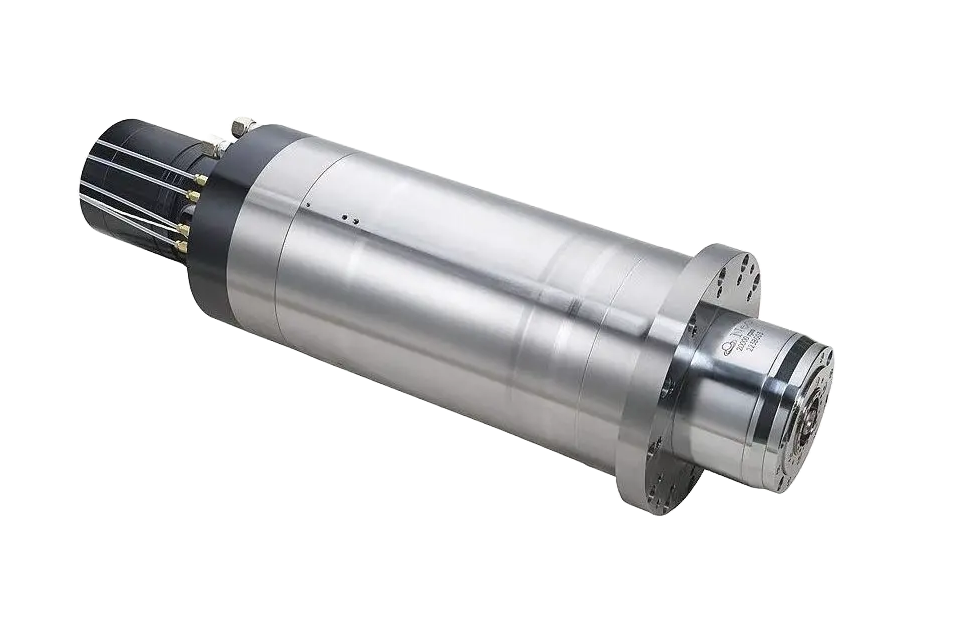

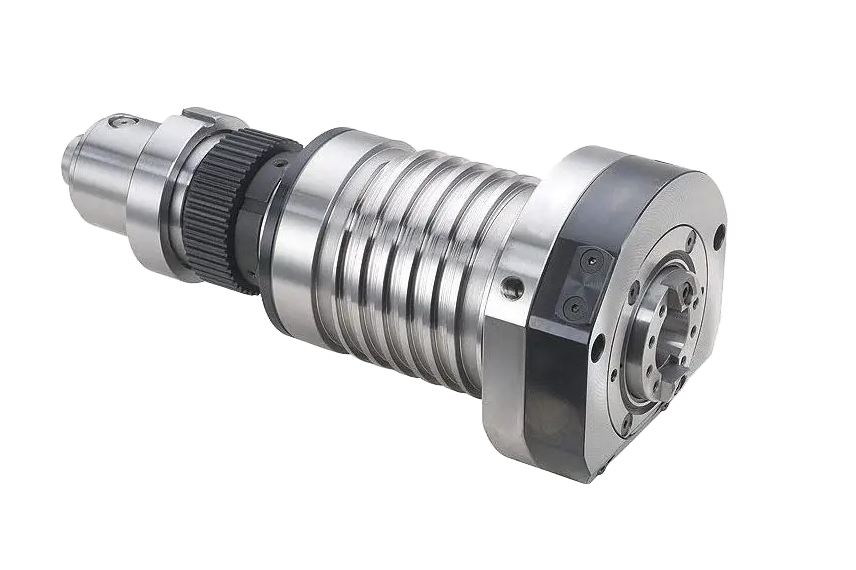

Quality Assurance and Testing

Setco is an ISO 9001:2015 certified spindle manufacturer that prioritizes quality. Our in-house quality management systems focus on continuous improvement and consistent business practices, enabling us to keep raising the bar.

All our spindles and other products undergo a comprehensive inspection process to verify they meet the highest quality standards. They also undergo rigorous testing to ensure that their performance will meet and exceed our customers’ expectations.