Machine tool spindles are precision components that require the highest level of care and handling. When performing repair and maintenance or sending a spindle in for service, follow these essential safety tips to protect your investment.

Take care to protect your spindles even when not in use. It is possible to damage a spindle by improper storage. Store the spindle where there is no risk of collision or excessive vibration. Vibration can cause severe bearing damage when the spindle is not rotating. Use internal and external lubrication to protect against corrosion. Storage areas should be clean and dry, with a stable temperature of 65 to 120 degrees F (18 to 49 degrees C) and at a non-condensing humidity level. This will help prevent contamination from entering the spindle assembly.

Only operate the spindle assembly at speeds above its nameplate rating. If overspeeding occurs, the spindle may fail due to excessive heat. Do not operate the spindle assembly at rates lower than its nameplate rating. If under-speeding occurs, the spindle may perform poorly. If you ever need assistance with a spindle of any make or model, you can contact the SETCO service team for help.

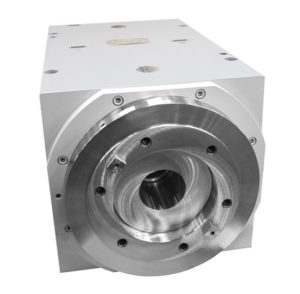

Many complex machines can only perform optimally with an appropriate and correctly maintained spindle. Relying on the experts is the best way to ensure spindles function as they should. Setco is a leader in spindle design, manufacturing and repairs, and we supply spindles of all types to support various industries and applications.

Whether you need to purchase new spindles or repair and maintain your current spindles, our skilled technicians and engineers can help. Browse our product selection or contact us to learn more about our services today.