Setco is an international company that serves spindle applications for a wide range of industries. We are fortunate to be involved in things people rely on daily. One example is transportation. Whether by plane, boat, train, or car, Setco products help manufacturers in the transportation industry build products you use every day.

In the airline industry, our new precision spindles are used in many areas of the plane. From engines to wing structures to seats, Setco spindles machine wing spars that support the plane structures, engine components to power the plane, and even seat brackets that hold the seats to the floor.

Setco has spindle uses for robotic applications as well. Mounting a precision spindle to the end of a robot allows manufacturers to perform cut-off operations, milling, drilling, tapping, and de-burring. The automation and efficiency a robot adds to the manufacturing process reduces costs. Combining robots with machining operations is increasing in popularity in manufacturing operations globally.

Friction stir welding is a challenging application that requires high thrust capacity and continuous loading. This process essentially takes two pieces of like metal and rotates a cylindrical tool at high speed between them to join the parts together. Setco custom designs spindles to handle these high-thrust loads.

Setco is heavily involved with the stone cutting industry. Stone cutting applications are challenging due to the harsh environment. Typically, cutting and grinding tools use a glycol solution for lubrication, rust prevention, and cooling. However, glycol will not work in stone cutting because it stains the material and ruins the finish. Instead, water is used, and it is not ideal for rust prevention, so the exposed metal of spindles takes a beating. Customizing spindles for this application requires specialty materials and coatings to protect the spindles from rusting.

Any deep hole internal grinding spindle has limitations on barrel extension length and diameter. We optimize the design to maximize spindle stiffness and provide customers with the best spindle by utilizing internal tools to perform FEA (Finite Element Analysis) prior to manufacturing. Our SEG spindles are used to grind honeycomb used in jet engines. These spindles use an electrical arc to precisely erode the honeycomb and leave it burr free.

Food processing offers its own unique challenges for precision spindles. With anything food related, the spindle must be designed to be food grade. This includes the internal and external components that could contact the processed food.

Setco spindles are also used in spin testing for various industries. The challenge of operating in these applications is typically the imbalance the spindle is exposed to during operation. Imbalance and vibration are detrimental to spindle life, and design engineers work to minimize these factors. In this application, spindles are typically exposed to high excitation forces. We work closely with customers to make sure the design and quality of our spindles maximizes spindle life.

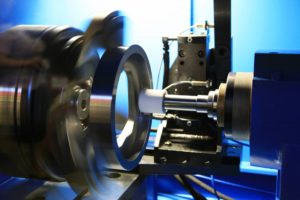

Modern manufacturing operations demand spindles that operate at wider speed ranges for increased functionality. As a result, Setco design engineers constantly push the edge of the envelope to design spindles with low speed and high torque capacity that cut metal as hard as titanium or higher speed capability to cut metal as soft as aluminum.

The range of spindle applications is almost endless. In addition to the applications already stated, Setco spindles are used for transmission testing, glass grinding, fiber winding, wire forming, ammo finishing, needle grinding, roll forming, and many other industrial applications.

Many complex machines can only perform optimally with an appropriate and correctly maintained spindle. Relying on the experts is the best way to ensure spindles function as they should. Setco is a leader in spindle design, manufacturing and repairs, and we supply spindles of all types to support various industries and applications.

Whether you need to purchase new spindles or repair and maintain your current spindles, our skilled technicians and engineers can help. Browse our product selection or contact us to learn more about our services today.